Looking to find some Ford diffs for sale? It can be a bit overwhelming with all the different options out there. Whether you’re working on a classic truck or a modern muscle car, knowing a bit about Ford’s axle history and what to look for can save you a lot of hassle. This guide breaks down some of the most common Ford differentials and related parts, giving you a better idea of what you might need for your project. We’ll cover the popular 9-inch, the versatile 8.8-inch, and the less common 8-inch, plus some other bits and pieces.

Key Takeaways

- The Ford 9-inch differential is a popular choice for its durability and the ease of swapping gears thanks to its removable third member, making it favored in racing.

- The Ford 8.8-inch axle is a common, strong option with good aftermarket support, featuring a Salisbury-style design and a common differential carrier across various gear ratios.

- The Ford 8-inch axle is a weaker, banjo-style differential often confused with the 9-inch; it’s typically found in lower-performance vehicles and is identifiable by how its case nuts are accessed.

- Axle identification tags, though often worn, can provide valuable information about the axle’s original ratio and features like limited-slip differentials.

- When looking for Ford diffs for sale, consider the specific application, the axle’s history (like dimples or drain plugs on 9-inch housings), and the condition of components like axle shafts and brake hardware.

Ford 9 Inch Differential

When you’re talking about rear ends, the Ford 9-inch is pretty much legendary. Seriously, this thing has a reputation for being tough, able to handle a ton of power without breaking a sweat. It’s no wonder why so many people building hot rods, custom cars, or race cars go for the 9-inch. It’s been around since 1957 and was made for a long time, so there are tons of them out there, and the aftermarket support is huge. Companies like Strange Engineering, Currie, Moser, and Mark Williams still make parts for them today, and you’ll even find them in NASCAR.

One of the best things about the 9-inch is its "third member." This is basically a whole chunk of the differential that you can pull out from the front of the axle housing. It makes swapping out gears or changing the type of differential super easy. If you’re into drag racing, this is a big deal because you can have different gear sets ready to go for different tracks or conditions. It’s a banjo-style axle, similar to the 8-inch, but way stronger.

The design of the 9-inch, with its removable third member and robust construction, is why it’s still so popular decades after it was first introduced. It’s a solid choice for anyone needing a reliable and strong rear axle.

There’s a bit of a difference in how the pinion gear lines up with the ring gear compared to newer axles like the 8.8-inch. The 9-inch has a larger offset, which is good for strength and can help with noise, but it can also create more heat. So, you’ll want to make sure you’re using good quality gear oil and that there’s decent airflow around the axle to keep it cool. Because they were made in such large numbers, you might find some that leak from the welds, but most shops can fix that up pretty easily. You can usually tell a 9-inch apart from an 8-inch by looking at the bolts holding the third member on; the 9-inch has a couple of bolts at the bottom that you can’t get a socket on, so you need a wrench.

Ford 8.8 Inch Axle

The Ford 8.8-inch axle is a really common find, especially in Ford trucks and some cars from the late 70s through the early 2000s. It replaced the older 9-inch and 8-inch axles in many applications, partly to save weight and improve fuel economy. Unlike the 9-inch, which has a cast iron third member that bolts in from the front, the 8.8-inch has its internals accessed from the rear by removing a stamped steel cover. This makes it a bit different to work on if you’re used to the 9-inch.

This axle uses 8.5-inch ring gears, which is a bit smaller than the 9-inch, but it’s still a pretty tough unit. It’s a semi-float design, meaning the axle shafts hold the wheels on, and they’re retained by C-washers inside the housing. This is different from a full-float axle where the axle shaft doesn’t support the vehicle’s weight. You’ll find a lot of aftermarket parts available for the 8.8, which is great for upgrades or repairs. The pinion on the 8.8 has a hypoid offset of 1.5 inches, which is less than the 9-inch’s 2.25 inches. This smaller offset is generally better for efficiency and less noise, though the 9-inch’s larger offset is often considered stronger.

While the 8.8-inch axle tubes are typically 3 inches in diameter, some folks find they can flex a bit under really high horsepower situations. For most street and moderate off-road use, though, they hold up pretty well. The good news is that the differential carrier itself is the same across different gear ratios, simplifying things if you decide to change your gearing.

Here’s a quick look at some common widths, though remember these can vary slightly by year and model:

| Model/Application | Typical Flange-to-Flange Width |

|---|---|

| Ford Explorer | ~60.5 inches |

| Ford Ranger | ~58 inches |

| Ford Mustang (Fox) | ~58.5 inches |

| Ford Mustang (SN95) | ~61.5 inches |

Keep in mind that these are general figures, and it’s always best to measure the specific axle you’re looking at. You might also find adhesive labels on the axle tubes with codes that can help identify the original gear ratio and whether it had a limited-slip differential.

Ford 8 Inch Axle

While the Ford 9-inch gets a lot of the glory, don’t forget about the Ford 8-inch axle. It’s a bit of a smaller sibling, often showing up in cars and trucks that weren’t built for heavy-duty hauling or serious off-roading. Think along the lines of Fairlanes, Falcons, and some of the earlier Mustangs and Pintos. It’s a banjo-style axle, similar to the 9-inch, meaning the whole differential assembly, or ‘third member,’ bolts onto the front of the housing. This makes gear swaps easier, which is a plus.

One of the easiest ways to tell an 8-inch apart from a 9-inch is by looking at the bolts holding the third member on. On the 8-inch, you can get a socket on all of them. On the 9-inch, a couple of those bottom bolts are tucked away, needing a wrench. The 8-inch axle generally uses a smaller ring gear than the 9-inch, making it less suited for high-torque applications. They were also typically only available with 28-spline axle shafts, which aren’t as robust as the 31-spline shafts you often find in 9-inch or 8.8-inch axles. If you’re building something mild, like a cruiser or a lighter vehicle, the 8-inch can be a perfectly fine option, but for anything that’s going to see a lot of stress, you’ll probably want to look elsewhere.

Many of these older 8-inch housings were made by welding together stamped steel pieces. This welding process, along with the drive for better fuel economy, eventually led Ford to phase them out. Because of this, you might find some leaks from the welds on used units. It’s not uncommon, and a good shop can usually fix them up.

| Feature | Ford 8 Inch Axle | Ford 9 Inch Axle |

|---|---|---|

| Ring Gear Size | Smaller | Larger |

| Axle Shafts | Typically 28-spline | Various, often 31-spline |

| Construction | Banjo-style | Banjo-style |

Axle Identification Tag

Finding the right Ford differential for your project often comes down to knowing exactly what you’re dealing with. One of the most helpful, though often missing, pieces of information is the axle identification tag. These little metal tags, usually found bolted to the third member housing, are like a VIN for your axle. They can tell you a lot about what’s inside, like the gear ratio and whether it came with a limited-slip setup.

The information on these tags can be a bit cryptic, but once you know what to look for, it’s pretty straightforward. The format has changed over the years, but generally, you’ll see a code that breaks down the axle’s specifics. The top line often starts with a model code, followed by a suffix that might indicate a revision, and usually ends with a date code. The bottom line typically starts with the gear ratio, followed by the ring gear diameter (like 8 or 9 inches), and sometimes a plant code. If you see an ‘L’ in the ratio section, that usually means it’s equipped with a Traction-Lok, or limited-slip, differential.

It’s pretty common for these tags to be missing or too corroded to read. If that’s the case, you’ll likely need to pull the third member out to check the gears and differential carrier directly. This can be a bit more involved, but it’s the only way to be sure.

Don’t be surprised if the tag you find doesn’t perfectly match the common formats. Ford sometimes used special tags for specific orders or different vehicle lines, so a little extra research might be needed if your tag looks unusual. It’s always a good idea to cross-reference any numbers you find with reliable Ford axle guides.

Pinion Cartridge

The pinion cartridge is a pretty important piece of the whole differential puzzle. It’s basically the housing for the pinion gear and its bearings. Think of it as the front support for the whole rotating assembly.

Different versions of the pinion cartridge exist, with some offering upgrades for tougher jobs. For instance, the Daytona-style cartridge is a popular choice because it lets you use a beefier pinion head bearing. This is a good move if you’re pushing a lot of power through your axle or just want a stronger setup when you’re replacing the old one.

The way the pinion gear is supported can really affect how well the whole axle holds up under stress. More support means less chance of things bending or breaking when you really put the pedal down.

When you’re looking at Ford differentials, especially the classic 9-inch, you’ll find that the pinion setup is a bit unique. It uses a straddle-mount design, meaning there are bearings on both sides of the pinion head. This adds extra stability, which is a big reason why the 9-inch has a reputation for being so tough. The offset of the pinion gear is also a factor here, influencing the size of the bearings and the support structure needed.

Axle Housings

The housing is basically the big metal pumpkin that holds all the gears and stuff inside your differential. For Ford axles, especially the older ones like the 9-inch and 8-inch, these housings were typically made by welding together a bunch of stamped steel pieces. It’s a pretty involved process, and sometimes, due to the high-volume production, you might find issues like leaks from those welds or maybe the housing isn’t perfectly straight. Aftermarket shops can often fix these problems, though.

The Ford 9-inch housing is famous for being super tough and able to handle a lot of power, which is why it’s still a favorite for custom builds and racing. Over the years, Ford made housings in all sorts of lengths and with different setups for brakes and suspension mounting points. You’ll see variations depending on the specific Ford model and year it came from. Some housings even had unique features, like the Shelby GT housing which tapered at the ends to save weight while keeping the center strong.

When you’re looking at housings, pay attention to the overall length, the type of brake mounting, and any specific features that might be important for your project. It’s not just a simple metal shell; it’s a key part of the axle’s strength and compatibility.

Later on, the 8.8-inch axle, which replaced the 9-inch in many applications, also used a similar construction method. While similar in concept to some GM axles, Ford engineers tweaked the design. You might find these housings with metal tags that provided service information, though these were eventually phased out. Different brake drum sizes and bearing setups also mean variations in the housing’s wheel end design.

Axle Shafts

Axle shafts are the pieces that actually transfer the power from the differential to the wheels. They’re pretty important, obviously. You’ll find a lot of variation here depending on the specific Ford axle model and the year it came from. Some shafts have different numbers of holes for brake backing plate bolts, or different shapes on the ends where they connect to the differential. Don’t sweat these small differences too much, though; they usually don’t affect the shaft’s strength.

Some older axle shafts, especially those with 31 splines made before 1973, could be shortened and have new splines cut. However, shafts with 28 splines are usually tapered and can’t be modified this way, and later 31-spline shafts (1973 and newer) typically can’t be resplined either.

When you’re looking at Ford 9-inch axles, you might see some unique designs. For instance, there was a special version for the 1960 F-100 that had one-piece tubes with no welds on them, just marks from the manufacturing dies. Then there are the Edsel axles, which had some unusual shaft designs with different brake spacing and a unique brake drum diameter. These also had a five-on-5-inch bolt pattern, which was pretty uncommon back then.

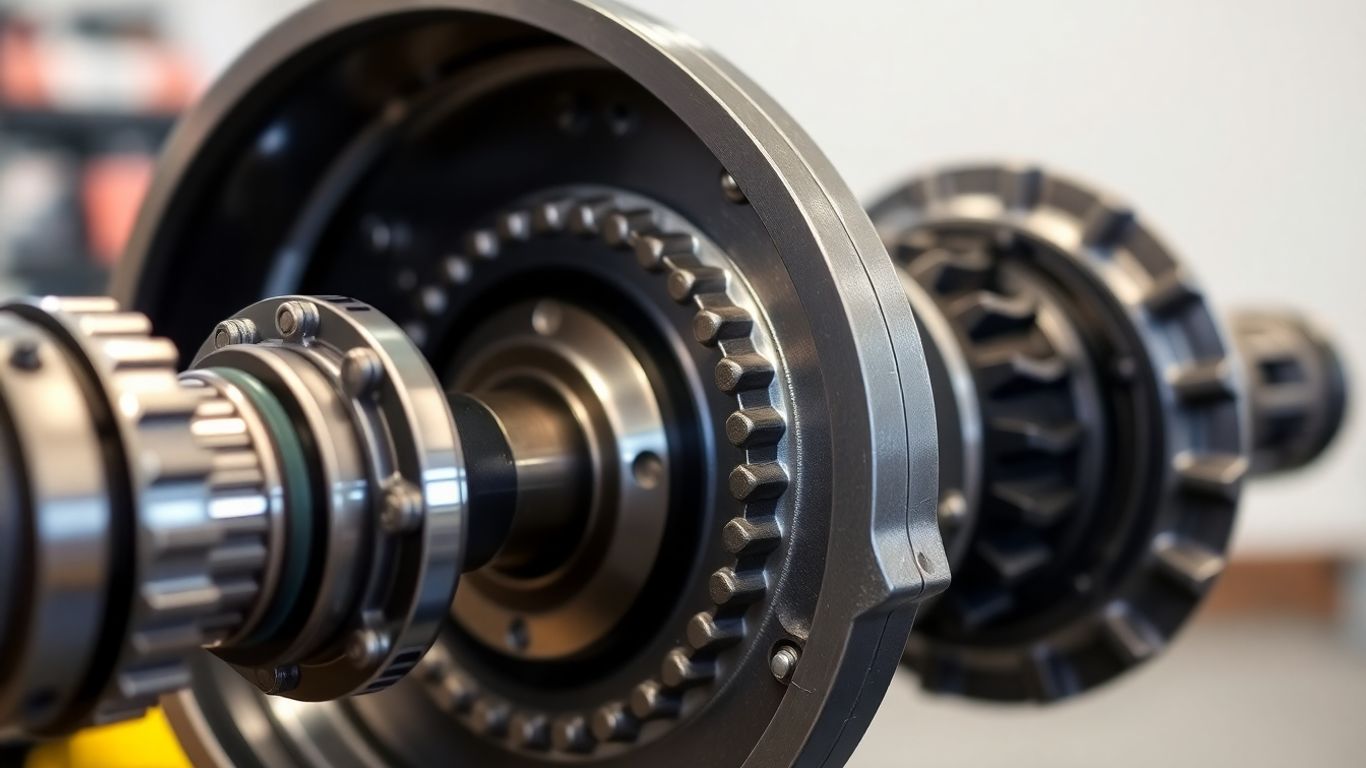

Differential Carriers

The differential carrier, sometimes called a "third member" in Ford 9-inch rears, is the heart of the whole differential setup. It’s where the magic happens, allowing your wheels to turn at different speeds when you’re cornering. Think of it as the housing for the gears that make turning possible.

Ford’s 8.8-inch axle is known for its versatility, as the same differential carrier can often be used across a wide range of gear ratios, unlike some other axle designs. This makes finding the right part a bit simpler. You’ll find these carriers in everything from Mustangs to F-150s. They’re generally robust, but like any part, they can wear out or break under heavy use.

When you’re looking for a replacement, you’ll see different types. There are "open" carriers, which are standard and send power to both rear wheels equally. Then there are "limited-slip" or "posi-traction" carriers, which help send more power to the wheel with better traction, especially useful if one wheel is on a slippery surface. For serious performance or off-roading, you might even find "locking" differentials, which force both wheels to turn at the same speed, giving you maximum grip but making tight turns difficult on pavement.

The material and design of the carrier can make a big difference in durability. Some are cast iron, others are aluminum, and higher-performance versions might use stronger steel alloys. It’s worth checking what your specific Ford axle came with or what upgrades are available.

Finding the correct carrier for your specific Ford axle model and year is key. Whether you’re rebuilding an old classic or upgrading for more power, the differential carrier is a component you don’t want to overlook.

Gear Ratios

When you’re looking for a Ford differential, the gear ratio is a pretty big deal. It basically tells you how many times the driveshaft spins for every single rotation of the rear wheels. Think of it like the gears on a bicycle – a lower number means you can go faster on flat ground, but it takes more effort to get going. A higher number makes it easier to accelerate from a stop or climb hills, but you won’t reach top speed as quickly.

Ford axles, especially the popular 8.8-inch and the classic 9-inch, are known for having a wide range of gear ratios available. This is great because it means you can really tailor your vehicle’s performance to what you need, whether that’s better fuel economy for highway cruising or serious grunt for towing and off-roading. The cool thing about the Ford 8.8 and 9-inch is that they use the same ring gear diameter across different ratios, unlike some other axles out there. This makes swapping ratios much simpler.

Here’s a general idea of what different ratios are often used for:

| Ratio Range | Typical Use |

|---|---|

| 2.73 – 3.08 | Highway cruising, better fuel economy |

| 3.23 – 3.73 | Balanced performance for street and light towing |

| 4.10 – 4.56 | Off-roading, heavy towing, better acceleration |

| 5.13+ | Extreme off-roading, very heavy loads, drag racing |

Figuring out the right gear ratio can really change how your vehicle feels. It’s not just about numbers; it’s about matching the axle’s performance to your driving style and what you use your vehicle for. If you’re unsure, it’s often best to start with a common ratio that balances everyday driving with occasional heavier use.

Brake Hardware

When you’re looking at Ford differentials for sale, don’t forget about the brake hardware. It’s a pretty important part of the whole setup, really. You’ve got different drum brake sizes, like 10 x 2-inch or 10 x 1¾-inch, and then there are the larger 11-inch diameter drums. These can come in various widths too, such as 1¾, 2¼, 2½, or even 3 inches wide.

The type of brake hardware you need often depends on the specific axle model and the year it came from. Some axles might have provisions for disc brakes, like the Lincoln Versailles setup from the 80s and 90s, which was popular for a while.

It’s not just about the drums, though. You’ll also find different wheel hub arrangements and brake backing plates. Some axle shafts have just one hole for the backing plate bolts, while others have three. It’s all about making sure everything fits together correctly for your particular Ford axle. Getting the right brake hardware is key to a safe and properly functioning rear end.

Wrapping It Up

So, you’ve learned a bit about finding the right Ford differential for your needs. Whether you’re looking at the classic 9-inch or the more common 8.8, knowing what to look for can save you a lot of headaches. Keep an eye out for those identification tags, understand the differences in housing and third-member designs, and don’t be afraid to ask for help from experts or check out reputable suppliers. Getting the right axle means your Ford will be back on the road, running strong.